Engineering Capabilities

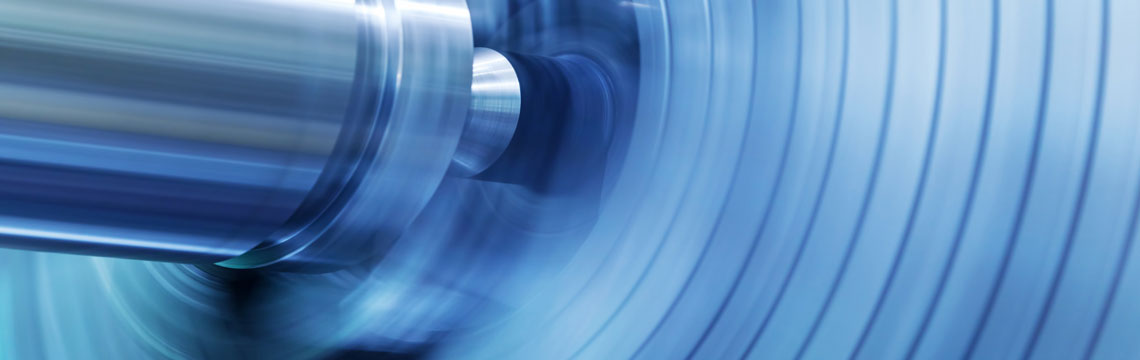

As an engineering, manufacturing and machining group we tend to need a lot of machinery to carry out the processes we require to sustain business we call this our group engineering capabilities.

The capabilities of the group accelerated during the 1980’s when AGENA technology was formed and subsequently all our capabilities became more bespoke to our increasing customer, business and industry requirements.

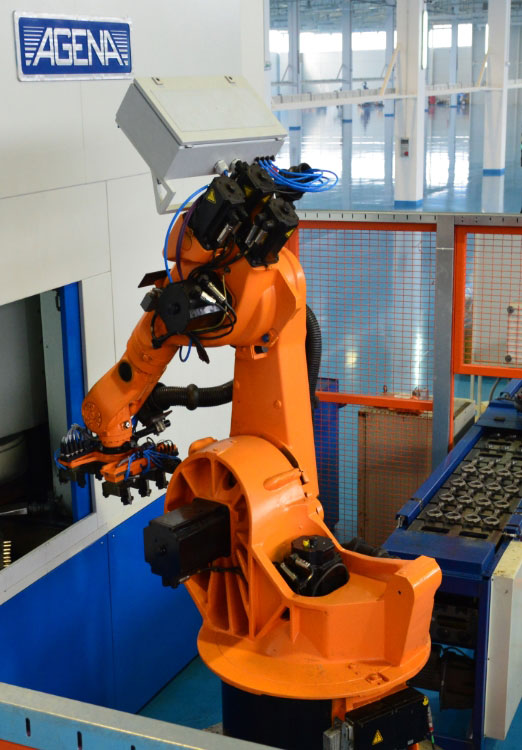

When AGENA was being developed it became a necessity and therefore a priority to build a design team that can develop any… and all turn key production machines. AGENA specialises in connecting rod machining technologies this is only one facet of our group capabilities.

Our technologies have evolved to keep in line and exceed industry tolerances over the years and our intention is for the historical success to be carried on into the future.

Due to our unique level of expertise in not only machining engineering components but also the machines required to produce them, the group achieves the level of quality, reliability and service required to exceed our customer expectations, we also have pioneering technology projects and are always happy to engineer a bespoke solution to customer manufacturing requirements and demands.

AGENA’s Large Scale Manufacturing Capabilities:

- Two large overhead cranes, weight rated at 20 Ton each crane. Used to move large machines and large machine parts to and from manufacturing to assembly etc.

- Our largest CNC machining centre (heavy duty) can machine products with the following dimensions: X - 6000mm, Y - 2000mm and Z - 1200mm.

- Design team highly experienced in designing large scale machines for many different sectors.

- Advanced machining techniques.

AGENA’s Other Capabilities:

- Tooling and Fixture design and production.

- Parts handling machines. Programme and build.

- Mechanical, Electrical, Hydraulic and Pneumatic design.

- Dedicated flexibility to its customers.

AGENA’s Other Machines:

- A Heavy-Duty CNC Machining Centre.

- Two middle duty CNC Machining Centres.

- Two Horizontal Milling Machines.

- One CNC Lathe.

- Ten Manual Lathes and Milling Machines.

- Three Surface Grinders.

- Two Cylindrical Grinders.

AGENA’s Computer Programmes:

- 3D CAD Software: Autodesk Inventor & ProEngineer.

- Electrical Design Software: WSCAD, EPLAN.

- CNC Machine Software: Fanuc, Siemens & NUM.

AGENA technologies and Albon engineering have developed their mutually beneficial relationship since both company’s conception, this has yielded many rewards for both. We have the advantage of knowledge, experience and design that can very easily be adapted.

The relationship between AGENA and Albon has developed and grown throughout the company’s history. There is a great ethos of helping and assisting with each other, this has had a remarkable effect on the growth of our group engineering capabilities.

Ongoing investment of new machinery has been vital to ensure that the group can continue to machine competitively and maintain keeping up with our customers supply and demand.

Albon’s connecting rods can range from below one litre engines at 50bhp for motorcycles, recreational & automotive vehicles up to 95 litre engines at 4000bhp for marine, locomotive and off highway applications. These are both conventional and fracture split joint face designs.

Albon’s capabilities of engineering can be mainly demonstrated by showing our manufacturing capabilities and machines available. Our manufacturing part volumes varies from 50 parts to 7000 parts per day, with production taking place on the latest state of the art machine tools, incorporating fully automated robot facilities.

Albon manufacture connecting rods for petrol, diesel & gas applications. Connecting Rod production is currently more than 5.5 million parts per annum. Albon have been manufacturing connecting rods ever since the company was established back in 1970 and now produce components for all major OEM producers. Albon is the nominated Tier 1 supplier to most of our customer base in the UK, Europe and the USA.

The company is now manufacturing Connecting Rods with profile (trumpet) bore small end bore minus the bush, with inclusion of coating to aid lubrication. Due to this development and research between Albon and one of our clients AGENA had the opportunity to make its own coating machine and has been successful on sale since 2016.

Robotics

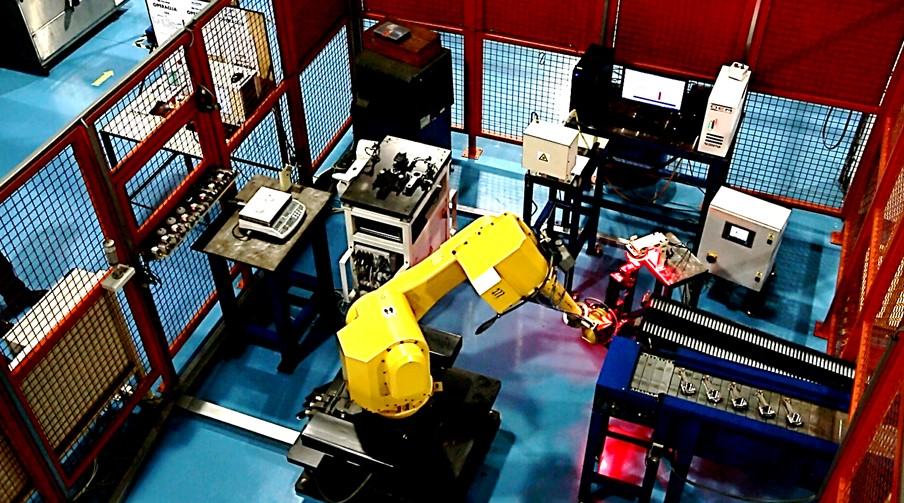

Robotics have been integral to Albon Engineering & Manufacturing PLC and AGENA Technology as the two companies have evolved. Our main use for robotics currently is machine tending robots, this offers consistent service 24/7 if required.

We use robots to replace human interaction where necessary, allowing the employee to focus on the quality assurance of the product. The main tasks of our robots are to move product from a supply position, transport it to a machine, orientate it and then interact with the machine. We have installed some manufacturing lines which are nearly fully automated by robotics. This approach is advantageous when the manufacturing schedules are medium to high volumes.

Our tending robotics capabilities have increased throughout Albon’ and AGENA’s expansion. This in turn has created a flexible approach that typical automation doesn’t offer.

A typical automation system requires much more human interaction. Machine tending is more complex as there is constant communication between robot and CNC machine. A general machine tending operation involves the robot to be much more active, it would replace all human interaction throughout the machining process, allowing emphasis to be focused on the quality of the component being machined rather than the laborious tasks of loading and unloading.

An added benefit of robotics is they function equally in challenging environments, minimising variation, maximising output in these conditions. They can handle lifting heavy loads, toxic or dangerous substances and repetitive tasks. Alongside our health and safety regime, this helps us to prevent many potential accidents.

The robots are more precise and consistent than human workers, they allow for increased production and profit margins because they can complete tasks faster, with no fatigue.

Creating a safe working environment is of paramount importance to Albon and must be carefully considered whenever planning to put a robotic machine in a factory with our employees, therefore we surround the robots with safety cages bolted to the shop floor and have input and output conveyors flowing in or out of the respective cordoned off area. Access into the robot cell is only granted to trained employees via a locked door.

What do Albon and AGENA do within the field of robotics?

- Albon & AGENA assemble, programme, test and maintain the robots.

- We have also developed multiple grippers for varied applications.

- The company and its employees have developed a robotic system that can 100% check for critical characteristics which would otherwise be impossible to achieve using human labour alone.

Want to find out more? Feel free to get in touch and one of our friendly team members will get back to you shortly.