Careers

Join Albon Engineering & Manufacturing PLC

Whether you’re an experienced professional, a recent graduate or beginning your career, working with Albon Engineering & Manufacturing PLC could be the challenging and rewarding career you are striving for. We’re investing time and effort into building our employees success. We’re looking forward to getting to know you and you can find our opportunities on our Vacancies page.

Albon’s managers and directors are more commonly willing to exercise their leadership in such a way that our employees are empowered to make decisions, share information and try new ideas. Most employees see the value in finding empowerment and are willing to take on the responsibilities that comes with it.

Our managers and directors try their best to create and build a working environment that empowers our staff members. Having an empowering management team requires our future leaders (employee’s) to have the ability to recognise the value in learning from the experience of the present leaders. This is one of many tools Albon uses to continue business growth and is very effective due to all parties benefiting from our Empower Your Future strategy.

Albon has been a successful family run business since it’s conception in 1970. Our success is down to our staff’s abilities and capabilities which enables Albon to develop.

Our management organisation plan can assist you in understanding the inner workings of Albon Engineering & Manufacturing PLC. This also gives a great insight to the different departments we use to operate.

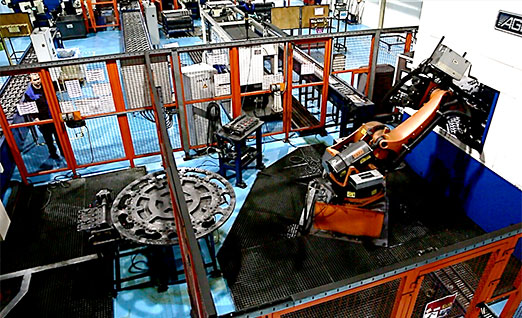

From Automotive components to large scale production of entire turn key production line solutions

Engineering

Quality – Albon is committed to the overall aim of achieving customer satisfaction by supplying high quality machined components and assemblies with minimum variation and cost.

Prototyping – With the ability to fine-tune designs accurately, it is of the utmost importance that the theoretical conn-rod design is reproduced the same in the physical component. Once a component design has been established numerous machining line techniques can be employed to design, build and install a manufacturing facility providing the best in class products.

Maintenance Engineering – Our maintenance team take care of all our manufacturing machinery and they use a planned preventative maintenance system.

Machine Setting & Programming – Everything from a simply pillar drill to large machining centres are set and programmed by Albon.

Manufacturing

Production - Albon can customise or change nearly any parameter within the production of its customers products.

Supply Chain - Is always developed and monitored. Changes made when necessary and an escalation process is in place to protect our customers and ourselves from causing manufacturing issues.

Logistics - Controlling and tracking the delivery of everything from a box of bolts to thousands of forgings.

Machining - All machining is completed in-house. Many different techniques have been developed over the course of our history.

Fixturing & Tooling - All fixturing and tooling is designed and manufactured in-house, this generates a more effective and faster route to mass production.

Operations

Sales & Marketing – Our team is responsible for providing research on opportunities within the markets, customer development research and to be the bridge between our customers and our internal teams.

Corporate Operations - From Finance to Human Resources to Maintenance, these teams ensure that Albon Engineering & Manufacturing PLC runs smoothly on a day-to-day basis.

Development Operations - Our development department works closely with our customers to develop greater machining techniques & processes, product composition analysis and other general product improvement ideology.

Purchasing Operations – Quality and cost are the main purchasing parameters analysed by our purchasing manager and team, among some other secondary parameters.

Computer Software -

- 3D CAD: Autodesk Inventor & Pro Engineer

- Electrical design: WSCAD & EPLAN

- CNC machine: Fanuc, Siemens & NUM

Turn Key Production Machinery - Albon uses the best in division machinery. We use a large amount of AGENA’s turn key production line solutions.

Staff health checks

Health checks on our staff members are conducted regularly to make sure our staff members are fit & healthy and subsequently safe. Generally, most staff members depending on their role will receive some form of health checks. Albon maintains their staff’s overall health by monitoring and checking the following criteria.

- Eyes Slight – Office workers using a computer for six hours or more a day and have been with the company more than three months receive fully supported eye checks and glasses if required. Factory staff will still have this checked to maintain our safe working environment.

- Hearing – The appropriate PPE will be provided to protect against any damage. Our staff’s quality of hearing will be checked regularly to make sure the Albon staff are all ears.

- Breathing - Air quality checks are completed regularly.

- Skin – Once again the appropriate PPE will be provided to protect against skin irritation, but factory staff will still be checked regularly during their health check.

Want to find out more? Feel free to get in touch and one of our friendly team members will get back to you shortly.